Lightweight design¶

Lightweight design is an engineering approach focused on minimizing the weight of a product or structure without compromising its performance in terms of stiffness, strength, functionality, or safety. This is generally achieved by employing a strategy involving:

- utilization of advanced lightweight materials, and

- optimization of the design topology and geometry within the constraints

Thus, lightweight design extends far beyond merely selecting and utilizing lightweight materials. In general, material substitutions without a comprehensive, holistic design or redesign process may result in only minor weight savings at a disproportionately high cost.

For instance, a traditional space frame constructed from metal profiles joined by welding can be an excellent and efficient solution for that material. However, simply replacing the metal with a composite material while retaining the original design is unlikely to succeed. This is because composite materials present significant challenges when joining components as if they were welded. While it's possible to achieve such a conversion, any potential weight savings would likely be minimal, and the solution would introduce several additional challenges.

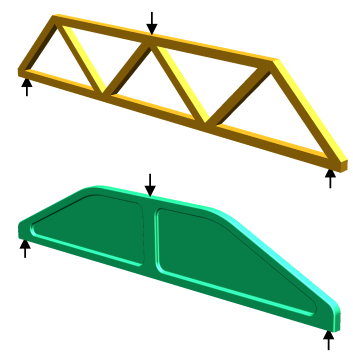

The proper approach is to take a step back and start by identifying the component's required functionality and constraints. Then, redesign the component with the specific strengths and weaknesses of the potential new materials in mind. The resulting structure will likely differ significantly from the original, perhaps taking the form of a smoother, more continuous shell-based design, as illustrated in the figure.

Who cares?¶

The importance of lightweight design varies significantly depending on the application. It is intuitively obvious that lightweight design is critically important for anything that shall fly, or even more generally, anything that moves.

Reducing the weight of an aircraft is paramount as it directly influences its fuel efficiency, range, and payload capacity. Every kilogram saved can lead to significant fuel savings over the lifespan of an aircraft, making lightweight materials and design strategies essential in the aerospace industry.

Similarly, ships and boats benefit greatly from lightweight design. A lighter vessel requires less propulsion power, which translates into lower fuel consumption and increased speed or range. In maritime design, where fuel efficiency is crucial for both economic and environmental reasons, reducing weight can also improve stability and maneuverability, enhancing overall performance.

Portable products, sports equipment, camping gear and basically anything that are moved by humans, form another category where lightweight design improves usability and convenience. The lighter these items are, the easier they are to handle and transport, making them more user-friendly and appealing.

A further category includes large-scale structures like bridges, skyscrapers and offshore rigs where the structure's own weight limits its height or span. In these cases, reducing weight pushes the boundaries of engineering possibilities, allowing for taller buildings and longer bridges, while also reducing the overall load on the foundations.

In all categories listed so far, lightweight design is both common and highly sophisticated. Beyond these specific applications, there are broader reasons to prioritize lightweight design: Reducing weight reduces the consumption of materials, which is simply beneficial on its own term.

Function and constraints¶

In engineering design, function refers to the specific purpose or role that a component, system, or product is intended to perform. It is the fundamental reason for the existence of the design and dictates how the design must operate to meet the desired outcome. The function of a design determines what it needs to do, how it interacts with other components or systems, and what performance criteria it must satisfy.

For instance, the primary function of a roll bar in a vehicle is to protect the occupants in the event of a rollover by maintaining the structural integrity of the cabin. It needs to withstand the forces exerted during a rollover, preventing the roof from collapsing and reducing the risk of injury. This function dictates that the roll bar must be made from a sufficiently stiff and strong, impact-resistant material. It should be strategically placed within the vehicle's structure to maximize protection while having limited weight and not obstructing the driver's view.

In the design process, identifying the function is one of the first and most critical steps, as it influences every subsequent decision, from the overall form and layout of the design to the selection of materials and manufacturing processes. Ensuring that the design fulfills its intended function is obviously essential for its success and effectiveness.

Constraints in engineering design refer to the limitations or restrictions that the design must adhere to. These constraints define the boundaries within which the design solution must be developed. They can be physical, economic, environmental, social, or regulatory in nature and are essential in guiding the design process to ensure the final product is feasible, safe, cost-effective, and compliant with standards.

- Physical and mechanical constraints: These include limitations related to the size, shape, weight, loading and boundary conditions. For example, a bridge must have a specific span length and load capacity.

- Economic constraints: Budget limitations or cost constraints that the design must meet. This includes both the initial cost of development and the long-term costs of maintenance and operation.

- Environmental constraints: These refer to the need for the design to minimize negative impacts on the environment, such as reducing emissions, conserving resources, or complying with environmental regulations.

- Technical constraints: These involve the technological limitations or requirements, such as the available technology, performance standards, or the need for compatibility with existing systems.

- Regulatory constraints: Legal requirements and industry standards that the design must comply with, such as safety regulations, building codes, and certification requirements.

- Time constraints: Deadlines or time limitations within which the design must be completed or the product must be delivered.

- Social and ethical constraints: Considerations related to the societal impact of the design, including user safety, accessibility, and ethical considerations.

Lightweight materials versus low-density materials¶

Lightweight design is often, and for a good reason, equated to the use of lightweight materials or low-density materials. However, there are significant nuances to this conception as the validity of this association is very dependent on the applications.

Lightweight materials and low-density materials are related concepts, but they are not exactly the same.

Low-density materials are materials that have a low mass per unit volume, meaning they are not very heavy for their size. Common examples include materials like aluminum and magnesium, polymers, polymer composites, many ceramics, wood and foams.

Lightweight materials is a broader term and refers to materials that contribute to the overall reduction of weight in a structure or product. While low-density materials are often used as lightweight materials, not all lightweight materials are necessarily low-density. The term lightweight also encompasses how the material is used in design, its mechanical properties, and how effectively it reduces the overall weight without compromising performance.

Density vs. design efficiency: A material can have low density but still be heavy, or contribute to a large mass, in a particular application if it requires a large volume to meet structural needs. Conversely, a material with a higher density can be used in a lightweight design if its strength allows for less material to be used overall.

Application-specific: Lightweight design often involves optimizing the material and its application, which can mean using advanced composites, sandwich structures, or other design techniques that minimize weight while maintaining performance. These techniques may involve materials that aren't necessarily low in density but are used in a way that contributes to a lighter overall structure.

Examples¶

For a stiffness based design of a tie rod, the mass needed to satisfy the constraints for an idealized problem is proportional to the density divided by the longitudinal modulus. That is,

where the constant $c_1$ incorporates all the constraints such as the length, force and allowed elongation.

A solution using generic steel will therefore have the mass

$$ c_1 \cdot \bigg( \frac{\rho}{E} \bigg) = c_1 \cdot \bigg( \frac{7850}{200} \bigg) = c_1 \cdot 39 $$We may try using a mangesium alloy, known for its application in extreem lightweight design:

$$ c_1 \cdot \bigg( \frac{\rho}{E} \bigg) = c_1 \cdot \bigg( \frac{1800}{45} \bigg) = c_1 \cdot 40 $$The result suggests that there is nothing to gain using magnesium over steel in this case. In fact, common enginnering metals will perform approximatly identical for this application:

materials = [ {'Name': 'Steel', 'rho':7850, 'E': 200},

{'Name': 'Titanium', 'rho':4500, 'E': 115},

{'Name': 'Aluminum', 'rho':2700, 'E': 70},

{'Name': 'Magnesium', 'rho':1800, 'E': 45}]

mass_steel = materials[0]['rho']/materials[0]['E']

print('Relative mass for a stiffness based tie rod:')

print()

print(' Material | Relative mass')

print('-----------------------------')

for mat in materials:

relativeMass = (mat['rho']/mat['E'])/mass_steel

text = ' {:10.10} | {:4.2f}'.format(mat['Name'],relativeMass)

print(text)

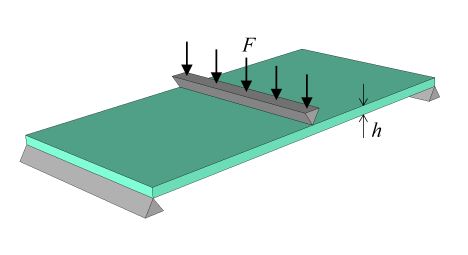

The story is very different for a stiffness based design of a panel.

The mass needed for the panel is

$$ m \ge c_2 \cdot \bigg( \frac{\rho}{E^{1/3}} \bigg) $$where the constant $c_2$ incorporates all the constraints including length and width, forces, boundary conditions and allowable deflection of the panel.

The expression now suggests that in order to save weight, it is more important to reduce the density than it is to increase the stiffness. Therefore, the weight of a magnesium solution is only 38% to that of a steel solution

Even lighter panels can be obtained by using a carbon fiber composite or wood (all fibers/grains along the bending stress):

materials.append({'Name': 'CFRP', 'rho': 1600, 'E': 140})

materials.append({'Name': 'Wood', 'rho': 500, 'E': 10})

mass_steel = materials[0]['rho']/(materials[0]['E'])**(1/3)

print('Relative mass for a stiffness based panel:')

print()

print(' Material | Relative mass')

print('-----------------------------')

for mat in materials:

relativeMass = (mat['rho']/(mat['E'])**(1/3))/mass_steel

text = ' {:10.10} | {:4.2f}'.format(mat['Name'],relativeMass)

print(text)

Rules for lightweight design¶

Achieving an optimal lightweight design can be a complex task, requiring careful consideration of materials, shapes, joints, and manufacturing constraints. This is where design rules become invaluable.

Lightweight design rules provide a structured approach to navigate the intricacies of balancing the overall performance. They help engineers make informed decisions, avoid common pitfalls, and optimize designs from the ground up. By following these rules, designers can ensure that every choice—from material selection to the use of joints—contributes to a lighter, more efficient, and cost-effective solution.

NOTE: There is no universally agreed set of rules for lightweight design. The ones listed here are inspired by several sources and have been specifically adapted to this course. These rules will be discussed in the theory and case studies.

1. Keep steel in the mix¶

Steel has relative high density, which makes it a rather counter intuitive solution in lightweight design. For that reason, steel is frequently excluded up-front in the process, something that may turn out to be a huge mistake.

It is likely not an overstatement to claim that steels are the most versatile group of engineering materials, being used in a countless number of applications for a reason: The combined performance due to high stiffness, strength, ductility, toughness and service temperature and relative low price is outstanding.

As demonstrated previously for a stiffness based lightweight design of a tie rod, steel is just as good as any of the more lightweight metals. When also including considerations related to strength, toughness, fatigue and cost, a steel solution can easily be proved to be the one with overall highest performance. Therefore, tie rods made of steel completely dominate the market, even for applications with exclusive emphasize on lightweight.

2. Do not overspecify¶

In lightweight design, the principle of less is more generally applies.The goal is to ensure that the solution performs its intended function without unnecessary additions. For example, a surfboard's primary functions are to ride the waves, withstand loads, resist water, and endure some impacts. While incorporating a refrigerator for cold drinks or specifying solid mahogany with a 5 mm clear coat might sound impressive, these features would deviate from the essence of a lightweight design.

Avoiding overspecification is important for several other reasons not exclusivly related to lightweight design:

Flexibility: Overspecification can limit the flexibility of the design, making it difficult to achive or adapt to new requirements, alternative solutions, or unexpected challenges. It may also restrict the choice of materials, suppliers or manufacturers.

Complexity Reduction: Adding unnecessary details or stringent requirements can complicate the design process, increasing the likelihood of errors and difficulties in all stages of the process.

Cost Efficiency: Overspecifying can lead to the use of more expensive materials, components, or processes than necessary, driving up costs without adding proportional value. Keeping specifications realistic helps manage the budget effectively.

Resource Optimization: Overspecifying can lead to the overuse of resources, including time, labor, and materials. By focusing only on what's essential, resources are used more efficiently, promoting sustainability and reducing waste.

Innovation Stifling: Strict and unnecessary specifications can stifle creativity and innovation by limiting the ability to explore alternative approaches that might be more effective or efficient.

3. Utilize the design space¶

Design space refers to the range of possible designs or solutions that can be considered when solving a particular problem or creating something new. It represents all the variables, parameters, and constraints that can be adjusted or explored in the process of designing a product. Hence, it is the conceptual framework within which designers explore, iterate, and optimize potential solutions.

The geometrical space is one of the items in the design space of a product.

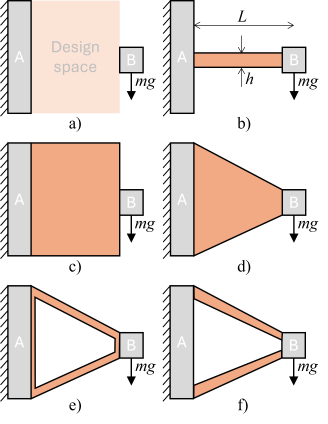

Example: Consider the two components, A and B in the figure to the right: Component A is fixed and shall be connected to component B, the latter beeing subjected to a gravitational force.

Illustration a) shows the boundaries of the geometrical design space for the connector.

The solution b) is basically a cantilever beam that does not utilize much of the possible space and will be exposed to relatively high bending stresses.

Solution c) utilize the space to the maxium. A large portion of the material will however not be exposed to any significant section forces and may just as well be removed as illustrated in d).

Material in the middle of the connector will not contribute much and can be removed or distributed differently as in illustration e).

Finally, assuming that there are no constraints related to the number of parts in the connector, the solution f) may emerge as the most optimum with respect to minimizing the mass.

Relevant case study: Lightweight drive shaft

4. Shape and material: design with synergy in mind¶

The selection of material inherently determines certain aspects of shape while the shape of a component can amplify or mitigate the effects of a material's properties. Thus, the shape of a component is not merely an aesthetic choice but a critical factor that influences and is influenced by the material from which it is crafted. Together, shape and material dictate the functionality, durability, and efficiency of the engineering element.

In advanced applications, this synergy becomes even more critical. Consider aerospace engineering, where components must be both lightweight and show high performance with respect to strength, stiffness and so on. Here, the choice of materials like carbon fiber composites is as much about their ability to conform to specific aerodynamic shapes as it is about their intrinsic material properties. The shape is designed not only to fulfill a mechanical function but to work in harmony with the material’s capabilities, ensuring optimal performance under extreme conditions.

Thus, the relationship between shape and material is a dynamic dialogue in the design process. Each influences the other in a delicate balance that defines the success of the engineering component.

5. Joints are necessary evils – avoid them when you can¶

Joints are often absolutely necessary for several reasons:

- They are integral parts of the function, such as in mechanisms.

- Materials need to be combined where seamless joining is not possible.

- It may be impractical or unfeasible to manufacture a seamless component due to size or complexity constraints.

In many situations, joints arise in the design as a result of balancing performance, cost, and manufacturing capabilities.

The major challenge with joints in lightweight design is straightforward: joints add weight compared to a seamless design. Not only do the components used to join different parts add weight, but the parts being joined will likely require additional materials and reinforcements.

Highly loaded composites, for instance, are notoriously difficult to join using simple mechanical joints like bolts.

Therefore, avoiding joints in lightweight design should be prioritized.

6. Keep on optimizing¶

It is easy to end up with a suboptimal solution; that is, the optimized design may only be at a local maximum in the design space. Therefore, make sure to explore the entire design space.