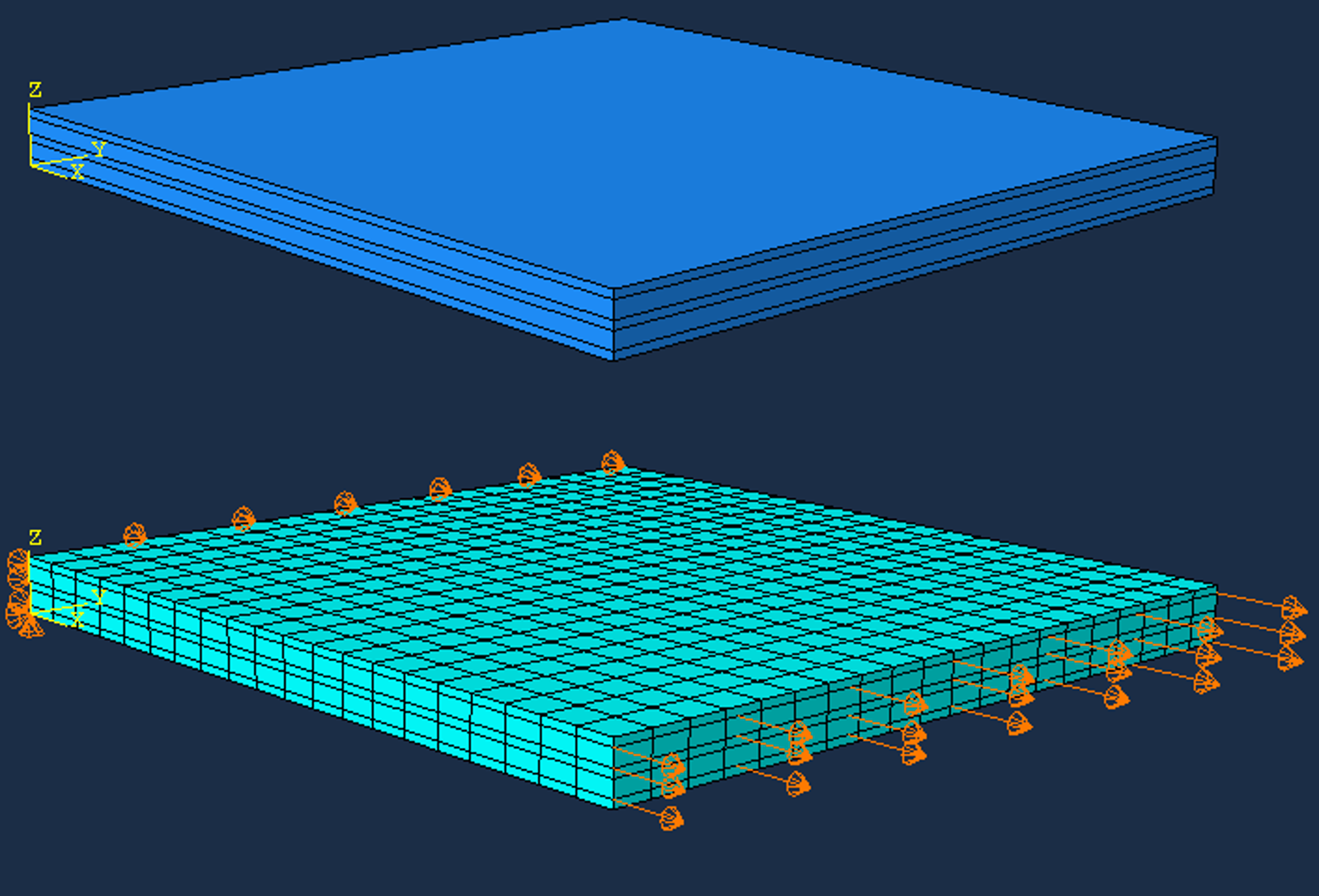

Solid laminate¶

A solid laminate implies a laminate made of solid elements where each layer is a discret volume as described in Lightweight Design

The layup definition for the script is a list of dictionaries similar to the one found in Laminates from Lightweight Design. A material reference for a layer is however not an object, but a name.

The following example has five layers of the same material but with different thicknesses and orientations:

lam1 = [{'mat':'E-glass/Epoxy', 'ori': 0.0, 'thi': 1.0},

{'mat':'E-glass/Epoxy', 'ori':-45.0, 'thi': 2.0},

{'mat':'E-glass/Epoxy', 'ori': 0.0, 'thi': 1.0},

{'mat':'E-glass/Epoxy', 'ori': 45.0, 'thi': 2.0},

{'mat':'E-glass/Epoxy', 'ori': 0.0, 'thi': 1.0}]Lists of parameters are generated from the laminate definition:

tk = [layer['thi'] for layer in laminate] # list of thicknesses

t = sum(tk) # total thickness

zk = [sum(tk[0:i])+tk[i]/2.0 for i in range(0, len(tk))] # list of z-coordinates to the midle of layers

orientations = [layer['ori'] for layer in laminate] # list of rotation angles

materials = [layer['mat'] for layer in laminate] # list of material namesThe complete script for one load case:

from abaqus import *

from abaqusConstants import *

def matlib(modelname):

mod = mdb.models[modelname]

mat = mod.Material('E-glass/Epoxy')

mat.Density(table=((2000e-12, ), ))

mat.Elastic(type=ENGINEERING_CONSTANTS,

table=((40000, 10000, 10000, 0.3, 0.3, 0.3, 3800, 3800, 3400,), ))

mat.Expansion(type=ORTHOTROPIC, table=((7E-06, 22E-06, 22E-06), ))

lam1 = [{'mat':'E-glass/Epoxy', 'ori': 0.0, 'thi': 1.0},

{'mat':'E-glass/Epoxy', 'ori':-45.0, 'thi': 2.0},

{'mat':'E-glass/Epoxy', 'ori': 0.0, 'thi': 1.0},

{'mat':'E-glass/Epoxy', 'ori': 45.0, 'thi': 2.0},

{'mat':'E-glass/Epoxy', 'ori': 0.0, 'thi': 1.0}]

def solidLaminateA(modelname, L, b, laminate, esize, ex):

tk = [layer['thi'] for layer in laminate] # list of thicknesses

t = sum(tk) # total thickness

zk = [sum(tk[0:i])+tk[i]/2.0 for i in range(0, len(tk))] # list of z-coordinates to the midle of layers

orientations = [layer['ori'] for layer in laminate] # list of rotation angles

materials = [layer['mat'] for layer in laminate] # list of material names

# new model:

mod = mdb.Model(name=modelname)

# materials and sections:

matlib(modelname)

for matname in mod.materials.keys():

mod.HomogeneousSolidSection(name=matname, material=matname, thickness=None)

# sketch and solid extrusion:

ske = mod.ConstrainedSketch(name='__profile__', sheetSize=200.0)

ske.rectangle(point1=(0.0, 0.0), point2=(L, b))

prt = mod.Part(name='P1', dimensionality=THREE_D, type=DEFORMABLE_BODY)

prt.BaseSolidExtrude(sketch=ske, depth=t)

del mod.sketches['__profile__']

session.viewports['Viewport: 1'].setValues(displayedObject=prt)

# Partitions (creating layers):

hk = 0

for i in range(0, len(tk)-1):

hk=hk+tk[i]

id=prt.DatumPlaneByPrincipalPlane(principalPlane=XYPLANE, offset=hk).id

prt.PartitionCellByDatumPlane(cells=prt.cells, datumPlane=prt.datums[id])

# Sets, orientations and section assignments:

id = prt.DatumCsysByDefault(coordSysType=CARTESIAN).id

count = 1

for z,ang,mat in zip(zk,orientations,materials):

c = prt.cells.findAt(coordinates=((L/2.0, b/2.0, z),))

reg = prt.Set(name='Layer-'+str(count), cells=c)

prt.MaterialOrientation(region=reg, orientationType=SYSTEM, axis=AXIS_3,

localCsys=prt.datums[id], additionalRotationType=ROTATION_ANGLE,

angle=ang, stackDirection=STACK_3)

prt.SectionAssignment(region=reg, sectionName=mat)

count = count + 1

# Mesh:

prt.seedPart(size=esize, deviationFactor=0.1, minSizeFactor=0.1)

prt.generateMesh()

# Assembly:

ass = mod.rootAssembly

ass.DatumCsysByDefault(CARTESIAN)

ins = ass.Instance(name='P1', part=prt, dependent=ON)

# Load case: uniform tensile strain x-direction:

mod.StaticStep(name='Step-1', previous='Initial')

region = ass.Set(name='faces at x=0', faces = ins.faces.getByBoundingBox(xMax=0))

mod.DisplacementBC(name='fix ux at x=0', createStepName='Step-1', region=region, u1=0)

region = ass.Set(name='faces at x=L', faces = ins.faces.getByBoundingBox(xMin=L))

mod.DisplacementBC(name='displacement ux at x=L', createStepName='Step-1', region=region, u1=ex*L)

# Preventing rigid body motions:

region = ass.Set(name='v1-rb', vertices = ins.vertices.findAt(coordinates=((0,0,0),)))

mod.DisplacementBC(name='rb1', createStepName='Step-1', region=region, u2=0, u3=0)

region = ass.Set(name='v2-rb', vertices = ins.vertices.findAt(coordinates=((0,b,0),)))

mod.DisplacementBC(name='rb2', createStepName='Step-1', region=region, u3=0)

# Job and results

job = mdb.Job(name=modelname, model=modelname)

job.submit(consistencyChecking=OFF)

job.waitForCompletion()

odb = session.openOdb(name=modelname+'.odb')

solidLaminateA(modelname='Lam1', L=100.0, b=100.0, laminate=lam1, esize=5, ex=0.01 )

Example¶

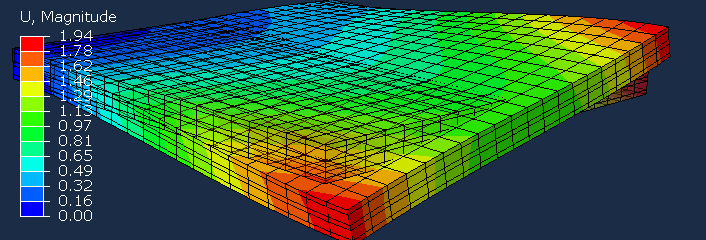

The result from the script as given, shows that the laminate twists when subjected to the uniform strain $\varepsilon_x$ as expected from the anti-symmetric layup.

Observe that the boundary conditions constrains the deformations for the faces at x = 0 and x = L such that they remain plane after deformation. That is not the case for the faces at y = 0 and y = b.

See also a modified and extended script in the example Laminate edge effects.