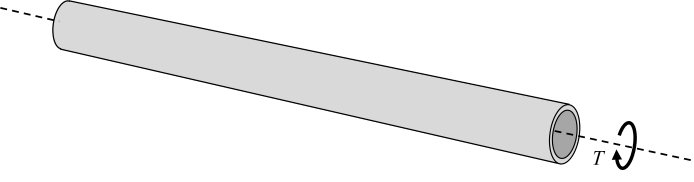

Composite drive shaft¶

Assumptions: the drive shaft can be approximated to a thin-walled tube where edge effects are neglected, see the case studies Lightweight drive shaft and Thin-walled pipes.

The relation between the shear section force $N_{xy}$ and the torque $T$ is now

\begin{equation} N_{xy}=\frac{T}{2\pi R^2} \tag{1} \end{equation}Hence, the governing set of equations is:

\begin{equation} \begin{bmatrix} 0 \\ 0 \\ N_{xy} \end{bmatrix} = \begin{bmatrix} A_{xx} & A_{xy} & A_{xs} \\ A_{xy} & A_{yy} & A_{ys} \\ A_{xs} & A_{ys} & A_{ss} \end{bmatrix} \begin{bmatrix} \varepsilon_x^0 \\ \varepsilon_y^0 \\ \gamma_{xy}^0 \end{bmatrix} \tag{2} \end{equation}For a balanced laminate, the only non-trivial equation is:

\begin{equation} N_{xy}=A_{ss}\gamma_{xy}^0 \tag{3} \end{equation}Solution for a homogenous isotropic drive shaft¶

From equation (1),

\begin{equation} \tau_{xy}=\frac{T}{2\pi R^2 t} \tag{4} \end{equation}The von Mises stress is now

\begin{equation} \sigma_{v}=\sqrt{3}\tau_{xy} \tag{5} \end{equation}Consider the following requirements and parameters for a steel shaft:

- Design torque: 5 kNm,

- Yield strength: 750 MPa (quite high yield strength)

- Fixed outer radius: 30 mm

- Wall thicness is a free parameter

Computing the required thickness and resulting mass per length:

In [1]:

from math import pi

import numpy as np

T=5E6 #Nmm

E,v,rho = 200000, 0.3, 7800E-12

G=E/(2+2*v)

Ro=30

def misesAndMass(t):

Ri=Ro-t

R=(Ro+Ri)/2

tau=T/(2*pi*t*R**2)

mises=(3**0.5)*tau

mass=rho*pi*(Ro**2 - Ri**2)*1E6

return (mises,mass)

thi = np.linspace(2,3,10000)

for t in thi:

mises,mass_steel=misesAndMass(t)

if mises<750:

break

print('Thickness= ',round(t,3),'mm')

print('Mises stress=',round(mises,1),'MPa')

print('Mass= ', round(mass_steel,3),'kg/m')

A carbon fiber composite solution:¶

In [2]:

import laminatelib

import matlib

import numpy as np

from numpy import pi

import matplotlib.pyplot as plt

m1=matlib.get('Carbon/Epoxy(a)')

def driveShaftStuff(angle,t,R,T):

layup =[{'mat':m1, 'ori':-angle, 'thi':t/2},

{'mat':m1, 'ori':+angle, 'thi':t/2}]

Ass=laminatelib.laminateStiffnessMatrix(layup)[5,5]

Nxy=T/(2*pi*R**2)

gxy0 = Nxy/Ass

deformations=np.array([0,0,gxy0,0,0,0])

res = laminatelib.layerResults(layup,deformations)

return res[0]['fail']

angles=np.linspace(30,60)

fE_MS = [driveShaftStuff(angle,t=1, R=30,T=5E6)['MS']['bot'] for angle in angles]

plt.plot(angles,fE_MS)

plt.show()

The optimum angle is clearly 45 degrees.

In [3]:

Ro=30

t=3.5

Ri=Ro-t

R=(Ro+Ri)/2

driveShaftStuff(45,t=t, R=R,T=5E6)

Out[3]:

In [4]:

mass_cfrp=m1['rho']*pi*(Ro**2 - Ri**2)*1E6

print('Mass pr. meter', mass_cfrp,'kg')

In [5]:

mass_cfrp/mass_steel

Out[5]: